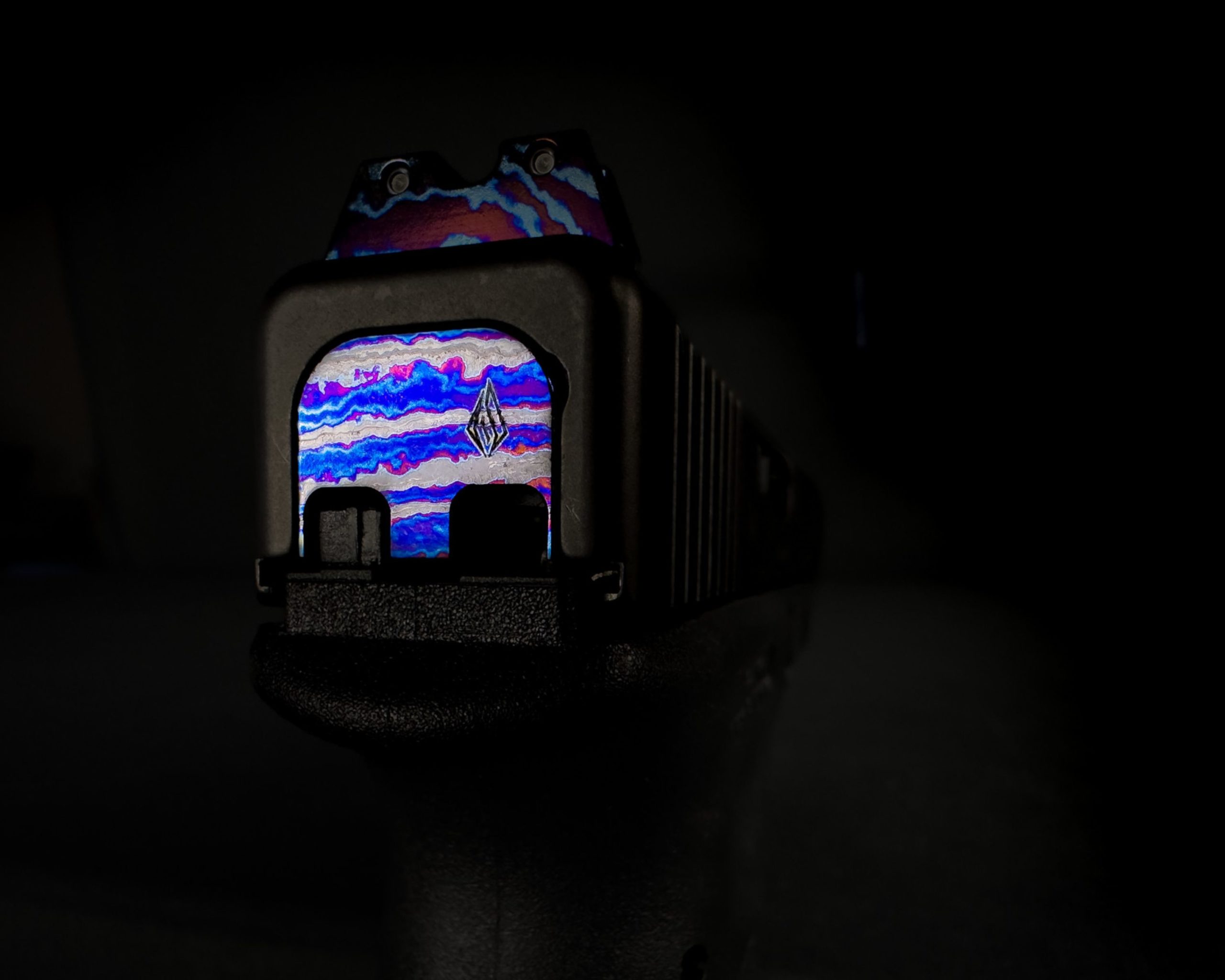

ZIRMASCUS GLOCK SLIDE PLATE

$145.00

The Burnyn Zirmascus Slide Plate combines the rawness of the forge, the precision of CNC machining and the detailed touch of a craftsman, all into one part.

Zirmascus, aka Zirc/Ti Damascus, that we forge at our Vegas Forge Shop, is a type of custom metal alloy that is made by fusing together 30 layers of Zirconium with 31 layers 6AL-4V aerospace Grade Titanium and 30 layers of commercially pure Grade 2 Titanium.

Zirmascus is known for its unique colorful appearance with dark grey accents, as well as it’s exceptional strength-to-weight ratio. It is highly resistant to corrosion and scratching making it an ideal choice for applications where durability and aesthetics are both important factors, such as in high-end knives, jewelry, and of course Firearms.

The nature of the rare material allows each part to have its own unique pattern.

Just like a fingerprint, no two will ever be the same.

Compatible with All Glock Generations (1, 2, 3, 4, 5)

Compatible with Glock Models – 17, 17L, 19, 19X, 20, 21, 22, 23, 24, 25, 26, 27, 28, 29, 30, 30sf, 31, 32, 33, 34, 35, 36, 37, 38, 39, 40, 41, 44, 45

Description

MATERIAL:

Random Pattern Zirmascus, that we forge ourselves at our Vegas Forge Shop, is a type of custom metal alloy that is made by fusing together over 120 layers of Zirconium, 6AL-4V aerospace grade titanium and commercially pure Grade 2 titanium.

Zirmascus is one of the coolest materials that Vegas Forge makes. You get the vibrant blues and purples from the layers of titanium that are contrasted with the dark greay layers of zirconium, pretty amazing! It is highly resistant to corrosion, making it an ideal choice for applications where durability and aesthetics are both important factors, such as in high-end knives, jewelry, and of course guns.

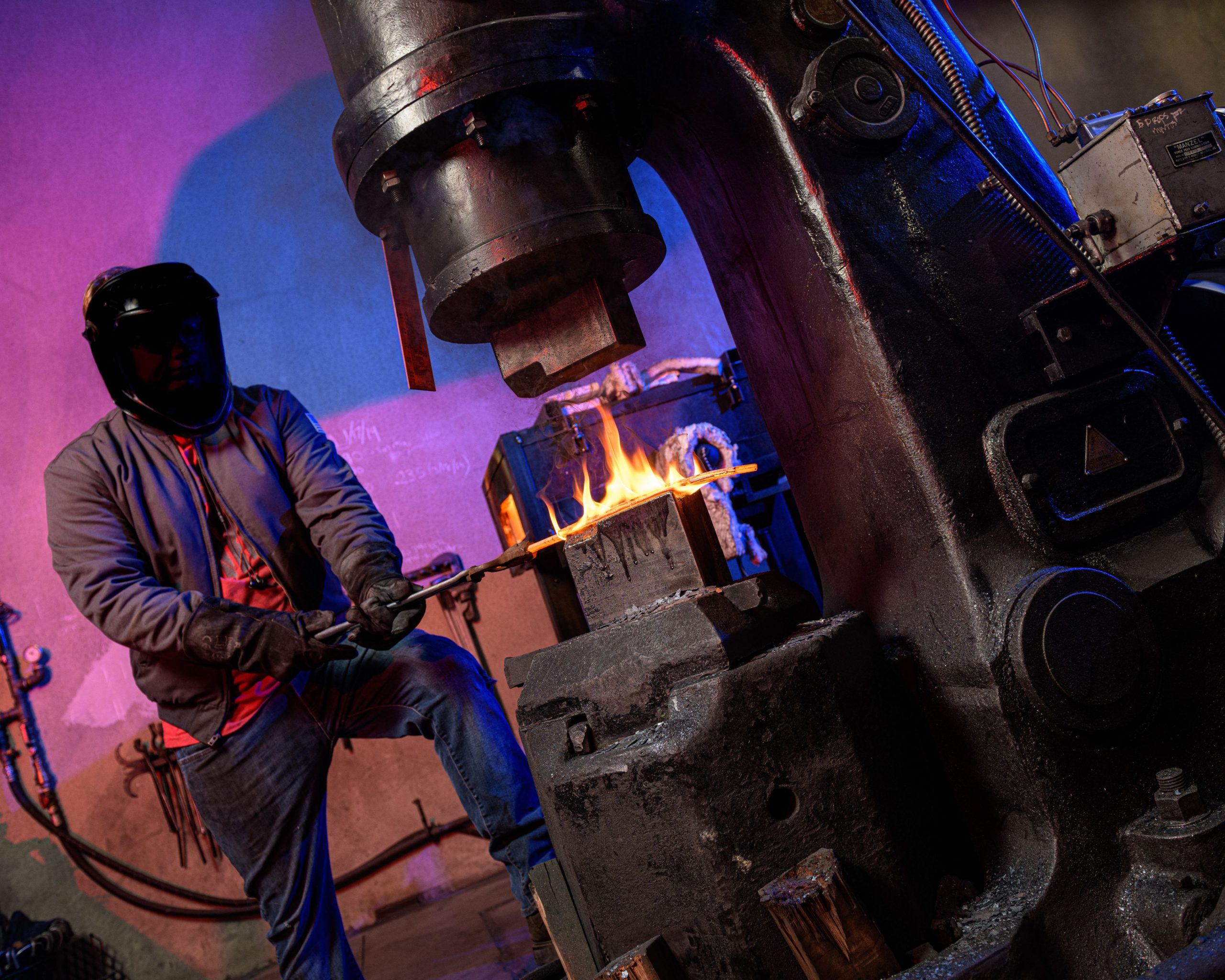

THE PROCESS:

Everything we do starts at Vegas Forge where we stack the layers of zirconium and titanium, heat to 1900 degrees and forge weld the layers together into one solid block. That material is then cut into sections, re-heated and hammered and rolled into custom sized billets. The billets are then surface milled in house to meet the size specifications needed for CNC machining.

The billets are then sent to Veteran owned small business “C & F Precision” in Henderson, Las Vegas where the material is CNC machined into a precision part.

The parts are sent back to us to deburr, tumble and check for quality. Each part is then hand sanded and buffed till the desired finish is achieved. Lastly, we use a torch technique to flame anodize each part which produces the vibrant colors you see on each of our finished Zirmascus products.

FAQ:

Will the color fade over time? The flame anodizing technique we use creates a strong barrier that is not easy to remove. We have put these parts to the test for over a year on our own daily carry. In and out of bags, under our car seats, etc and they still look as good as they did from day one.

Now let’s say that the part does fade after some years of extreme use, it’s no big deal to refinish. Just takes a quick bath in “Multi-Etch” and a re-flame with the torch to restore it back to new!

Reviews

There are no reviews yet.