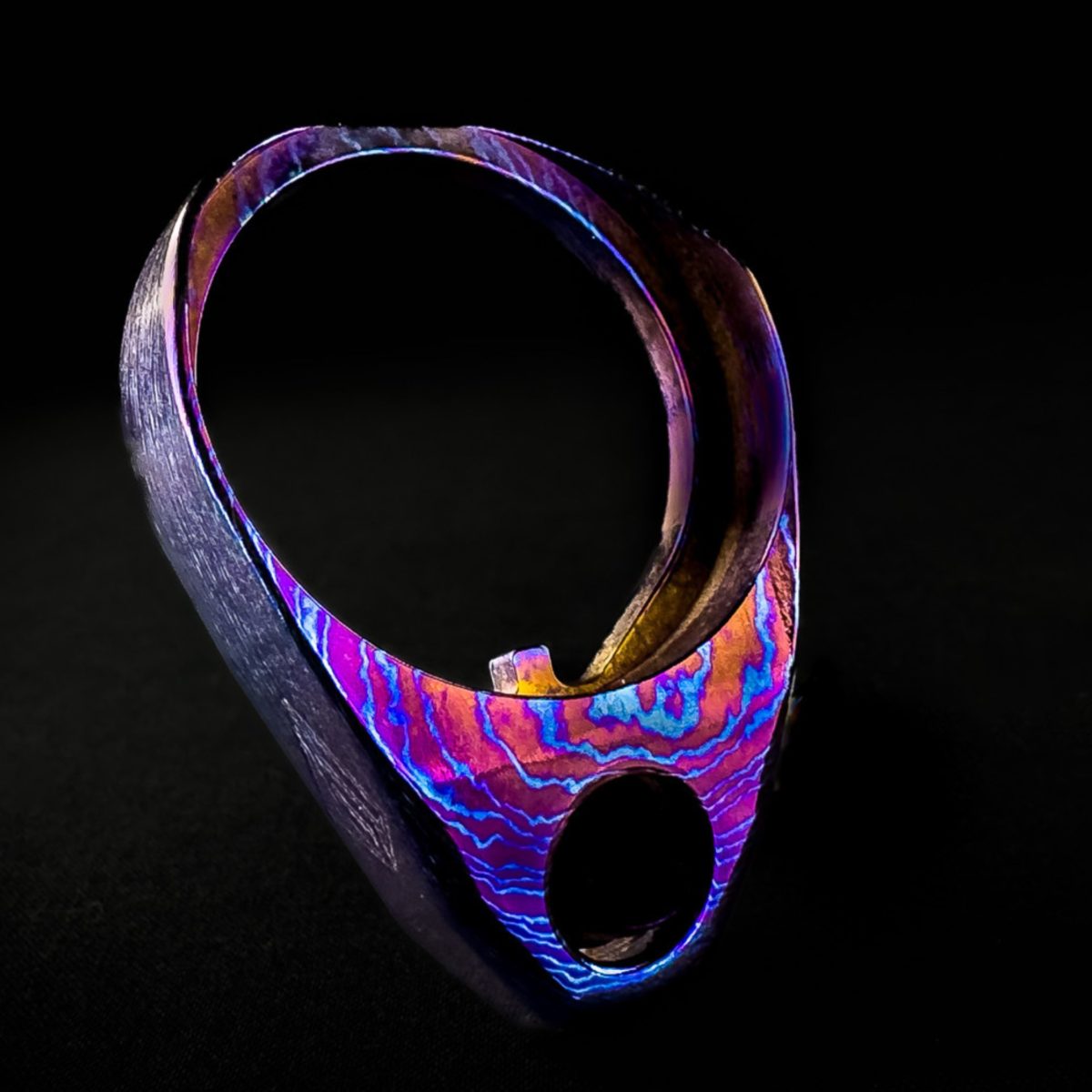

STAINLESS DAMASCUS QD RECEIVER END PLATE

$325.00

The Burnyn Stainless Damascus QD Receiver End Plates are a collaborative effort between Burnyn and Texas based CNC shop Griffworx.

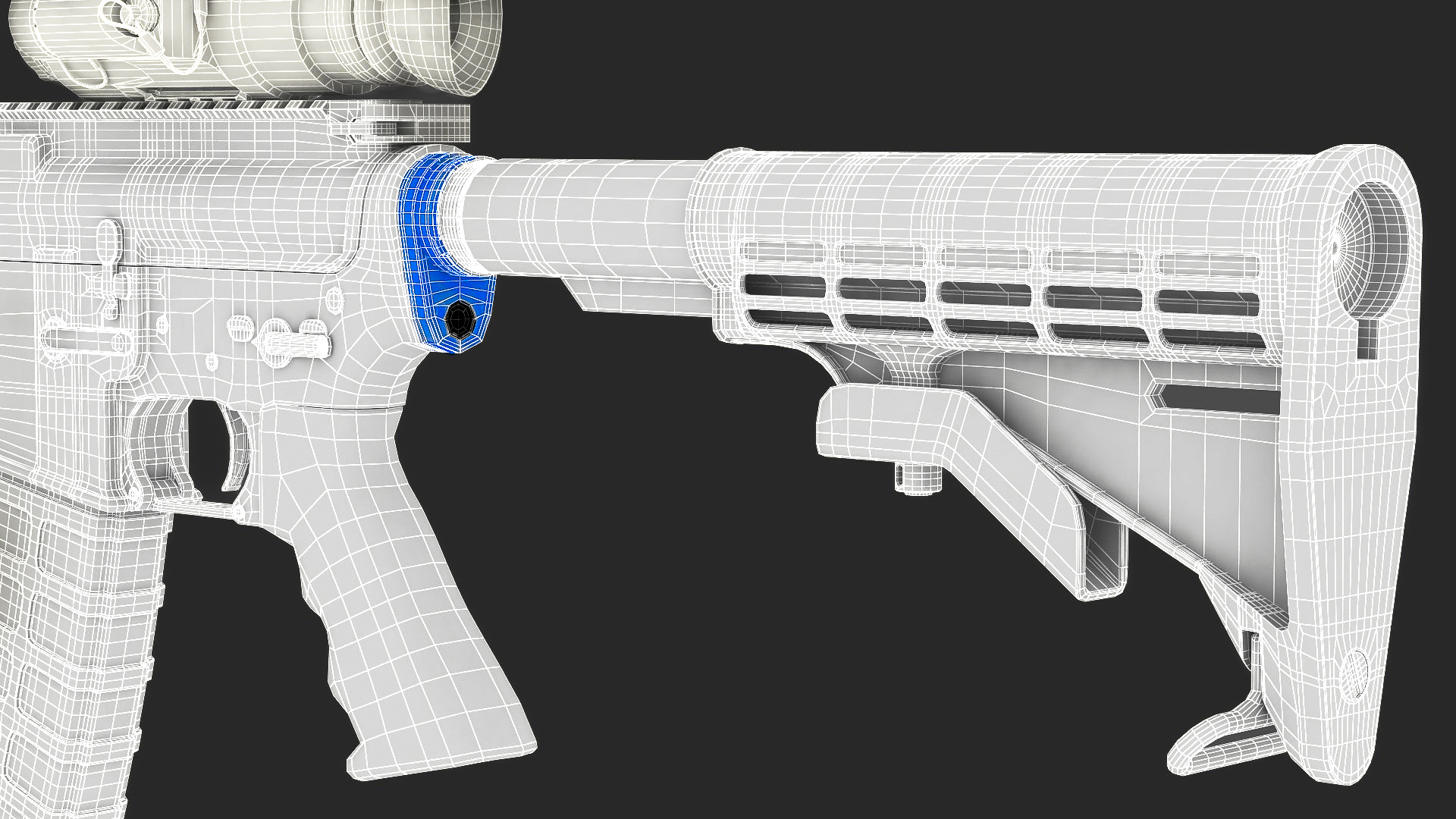

QD mount is at a 31 Degree angle from the lower receiver to allow a 360 Degree rotation for ambidextrous use. QD Sling Swivel Housing Designed with full Rotational Swivel Movement.

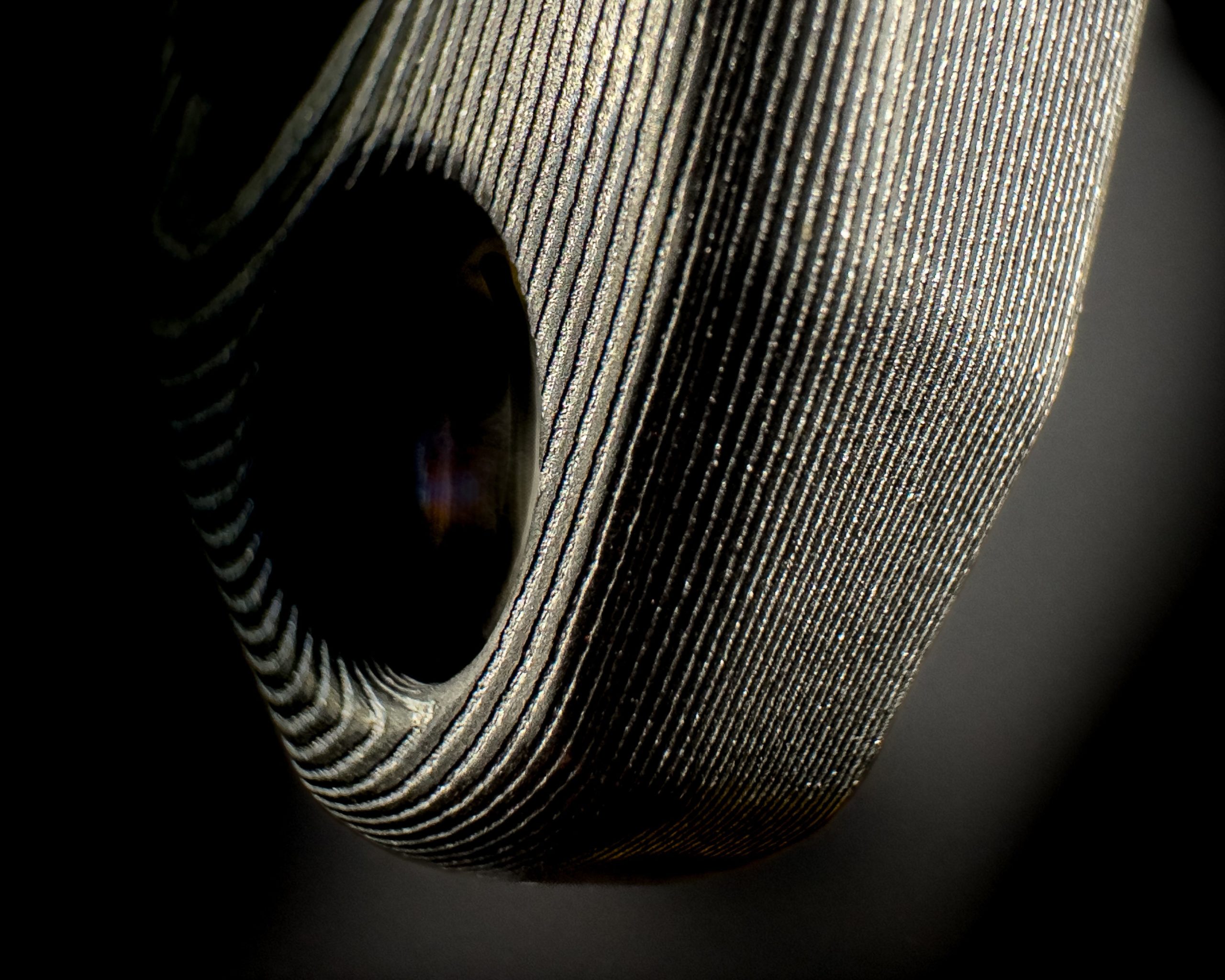

Stainless Damascus, that we forge at our Vegas Forge Shop, is a type of custom metal alloy that is made by fusing together 100 layers of Aeb-L razor blade steel with 99 layers of 302 high stainless steel.

This damascus combines the beauty of traditional damascus patterns with the corrosion-resistant properties of stainless steel, resulting in a stunning and durable material ideal for high-end pieces.

The nature of the rare material allows each part to have its own unique pattern.

Just like a fingerprint, no two will ever be the same.

Simple and Friendly Installation, No Permanent Modification Required.![]()

Compatible with nearly all (AR15, M4, .308), mil-spec carbine receiver extensions, commercial-spec receiver extensions and AR Variant lower receivers.

Accepts Any Quick Detach Sling Swivel with 0.37 inch Diameter Swivel Stud.

Description

DESCRIPTION:

The Burnyn Stainless Twist Damascus QD Receiver End Plates are a collaborative effort between Burnyn, Vegas Forge Damascus and Griffworx. Accepts Any Quick Detach Sling Swivel with 0.37 inch Diameter Swivel Stud. QD Sling Swivel Housing Designed with full Rotational Swivel Movement. Simple and Friendly Installation, No Permanent Modification Required.![]()

MATERIAL:

Stainless Twist Damascus, that we forge ourselves at our Vegas Forge Shop, is a type of custom metal alloy that is made by fusing together 199 layers of AEB-L razor blade steel with 302 high stainless steel.

Stainless damascus steel combines the beauty of traditional damascus patterns with the corrosion-resistant properties of stainless steel, resulting in a stunning and durable material ideal for high-end pieces.

THE PROCESS:

Everything we do starts at Vegas Forge where we stack the layers of two different stainless steels, heat to 2200 degrees and forge weld the layers together into one solid block. That material is then cut into sections, re-heated and hammered round, twisted and then rolled into custom sized billets. The billets are then surface ground on our Blanchard grinder to meet the size specifications needed for CNC machining.

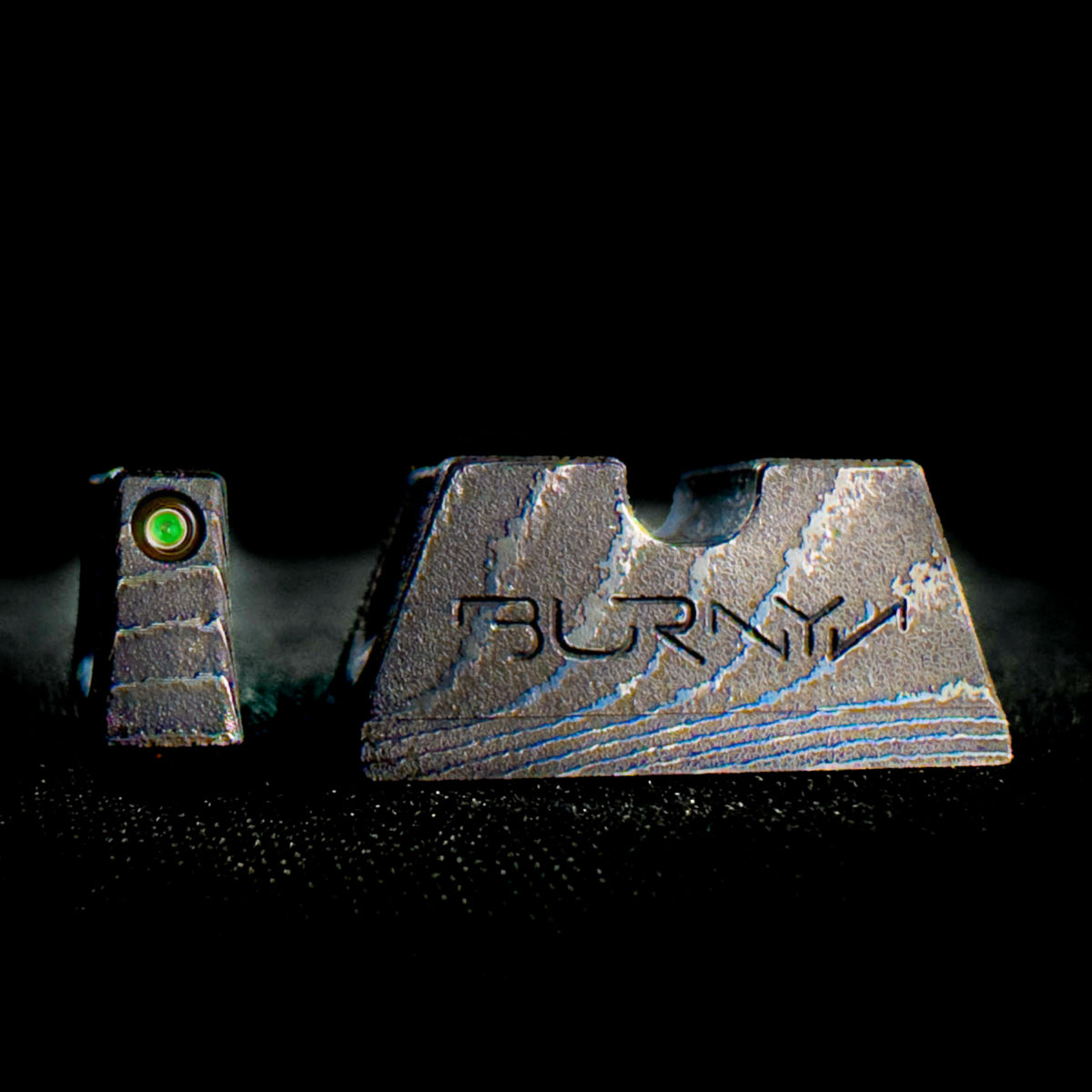

The billets are then sent to Griffworx in Texas where the material is CNC machined into a precision part.

The parts are sent back to us to deburr, tumble and check for quality. Each part is then heat treat hardened with a torch and hand sanded. Then each part is submerged into a bath of acid (ferric chloride) for 10 minutes which reveals the pattern of the damascus. Finally, we soak the parts in baking soda to neutralize the acid, dry and hand buff to polish the high points of the part.

FAQ:

Will the part rust? The stainless steel we use to make the damascus is very resistant to corrosion or rusting. As long as you don’t leave it all day in a wet bag, you’ll be good to go! These can always we refinished and is a service we offer our customers for a small fee.

Reviews

There are no reviews yet.